Contact person: Mr. von zheng guo

Position: 102600

Address: Financial Center D25, 3rd jinyuan Rd, Daxing District, Beijing China,102600

Country: China

Phone: 861061271490 - Mobi: 13683687926

foam concrete machine

Price: 11765

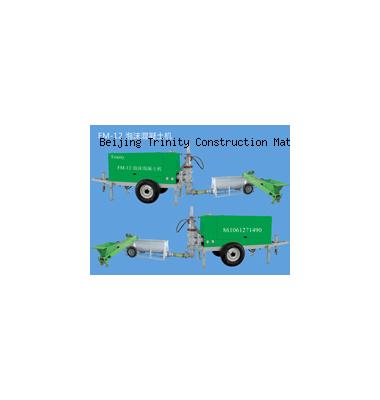

FM-12 Foamed Concrete Machine

I. Working Process

FM-12 includes four parts: belt feeder machine, mixer, foam generator, pump, it mixes cement, fly ashes, and water in a ratio in the mixer into cement slurry, it can mix from 200-1500kg/m3 density slurry and then transport cement slurry to high pressure pipe through pump. After foaming agent dilutes by water, it will be mixed with compressed air in a certain ratio, and therefore causes high density, closed-cell foam in the pipeline. In the final step, this foam will mix with cement slurry and turn into final product, foam concrete. (See complete processing diagram):

II. Technical Parameters

Value

Feed machine power 1.5kw

Mixer power 3kw

Foam generator power 1.5kw

Pump power 12kw

Max. output 12 m3/h

Vertical transport distance 80 m

Horizontal transport distance 300 m

Pump Pressure 5 mpa

Overall Dimension (L*W*H) 2.5×1350×1400 mm

Weight 1400 kg

Important Note: Above technical data are theoretical data, it depends on density of the foam concrete. Generally, lower density, higher pumping height.

III. Properties and Performance

With double cylinder hydraulic press to deliver concrete, FM-12 is able to meet higher construction needs because of its higher pumping ability.

1. Semi-automation controlling system controls mixing ratio of variety of materials refilling process;

2. Foam concrete’s density is easy to adjust;

3. high quality components; reliable after-sales services

4. Reduce construction cost;

5. Flexible mobility and positioning with road wheel

SEND INQUIRY

Please fill in fully your information to send email

CATEGORY

Agriculture

Agriculture