Supplier: Huatao Shale Shaker Screen Factory

Contact person: Ms. Annie Lu

Position: sale manager

Address: shijiazhuang,hebei,china

Country: China

Phone: 8631180690567 - Mobi: 8613930446984

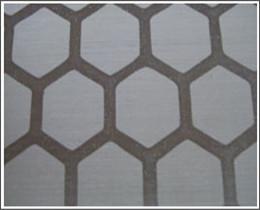

Steel Frame Shale Shaker Screen

Price:

Steel Frame Shale Shaker Screen

Steel frame screen are mostly applied to the shale shakers with wedge fastening equipment. The screen frames adopt that high-strength square steel tube welded to multi-ribbed construction. They are sturdy and reliable. These screens are constructed with two or three stainless steel layers bonded to a steel support plank. Accessary rubber plugs may be used to repair rips or tears. By doing this, we can cut down time and reduce the production costs. We can supply steel frame screens with mesh sizes ranging from 20 to 250.

Features of Steel frame screen

Ⅰ. Different layers with different density. To arrange these layers reasonably and exactly, the screening effect will become more and better.

Ⅱ.High strength frame, multi-ribs and the mesh cloth with moderate tension , from one reliable combination , which can increase screen’s acceptable flow , the intensity and the lifetime

Ⅲ.The wedge-shaped fastening device, can make the erection of screens more handily and quickly Ⅳ.The mesh divided into many independent small units by grids of the backing plate ,can prevent rips or tears from spreading overmuch. Accessory prepared rubber stoppers can be used to repair damage. By doing so, the operator can cut down the stop time and reduce the cost.

Screen Model Pange of Mesh Dimension(Length×Width) Brand & Model OF Shaker Weight(Kg)

HYK-1 16-325 585×1165mm SWACO MON900SE 12

HYK-2 16-325 635×1253mm BRANDT BL-50 13.5

HYK-3 16-325 913×650mm BRANTDT VSM-300 12.5

HYK-4 16-325 720×1220mm KEMTR ON KTL48 Series 17

HYK-5 16-325 712×1181mm SF300 17

Remarks: All the types above can be produced.

Annie Lu

Huatao Shale Shaker Screen Factory

http://www.shaleshakerscreen.info

annie.lu@huataogroup.com

Tel: +86 0311 80690567

Fax: +86 0311 85866720

Steel frame screen are mostly applied to the shale shakers with wedge fastening equipment. The screen frames adopt that high-strength square steel tube welded to multi-ribbed construction. They are sturdy and reliable. These screens are constructed with two or three stainless steel layers bonded to a steel support plank. Accessary rubber plugs may be used to repair rips or tears. By doing this, we can cut down time and reduce the production costs. We can supply steel frame screens with mesh sizes ranging from 20 to 250.

Features of Steel frame screen

Ⅰ. Different layers with different density. To arrange these layers reasonably and exactly, the screening effect will become more and better.

Ⅱ.High strength frame, multi-ribs and the mesh cloth with moderate tension , from one reliable combination , which can increase screen’s acceptable flow , the intensity and the lifetime

Ⅲ.The wedge-shaped fastening device, can make the erection of screens more handily and quickly Ⅳ.The mesh divided into many independent small units by grids of the backing plate ,can prevent rips or tears from spreading overmuch. Accessory prepared rubber stoppers can be used to repair damage. By doing so, the operator can cut down the stop time and reduce the cost.

Screen Model Pange of Mesh Dimension(Length×Width) Brand & Model OF Shaker Weight(Kg)

HYK-1 16-325 585×1165mm SWACO MON900SE 12

HYK-2 16-325 635×1253mm BRANDT BL-50 13.5

HYK-3 16-325 913×650mm BRANTDT VSM-300 12.5

HYK-4 16-325 720×1220mm KEMTR ON KTL48 Series 17

HYK-5 16-325 712×1181mm SF300 17

Remarks: All the types above can be produced.

Annie Lu

Huatao Shale Shaker Screen Factory

http://www.shaleshakerscreen.info

annie.lu@huataogroup.com

Tel: +86 0311 80690567

Fax: +86 0311 85866720

SEND INQUIRY

Please fill in fully your information to send email

CATEGORY

Agriculture

Agriculture