Supplier: Beijing Moon Technology CO., LTD.

Contact person: Mr. Jennifer Liu

Position:

Address: 1206, Building 1, 168 Beiyuan Road, Chaoyang District, Beijing

Country: China

Phone: - Mobi: 18614088770

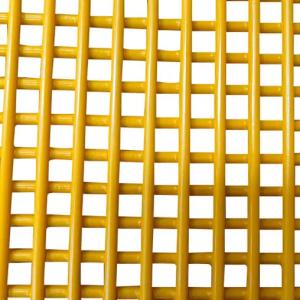

Polyurethane Wire Screen

Price:

Polyurethane Wire Screen

Polyurethane Wire Screen, also called polyurethane screen mesh or PU screen mesh, is a high-performance screening solution designed for industries that require efficient and durable material separation. Made from premium polyurethane material, this type of screen combines the flexibility and wear resistance of polyurethane with the structural strength of embedded steel wires. It is one of the most reliable options among polyurethane screens widely used today.

Introduction:

The polyurethane wire screen mesh is engineered to withstand the toughest screening environments. It offers superior wear resistance compared to traditional metal screens while maintaining structural integrity thanks to its embedded steel wire framework. This unique design ensures long-lasting performance, reduced downtime, and improved screening accuracy.

Applications span across mining, quarrying, aggregate production, recycling, and other heavy-duty industries, making PU screen mesh an ideal choice for material separation where durability and efficiency are critical.

Key Features

Material Options: Stainless steel (304, 316, etc.), carbon steel, or other alloy wires.

Slot Geometry: Parallel long slots with uniform width (e.g., 0.1mm–10mm) and customizable lengths.

Weaving Technique: Crimped pre-woven wires locked vertically and horizontally for rigidity.

Advantages: High throughput, anti-clogging design, wear resistance, and structural stability.

For additional screening options, you may also explore our polyurethane screen panels and other polyurethane screens.

Applications:

Our polyurethane screen mesh is widely applied in:

· Mining and Mineral Processing: Efficient separation of ores, coal, and aggregates.

· Aggregate and Sand Processing: Reliable performance in quarries and sand plants.

· Recycling and Waste Management: Effective for sorting scrap, plastics, and construction waste.

· Construction and Demolition: Screening concrete, rubble, and other demolition materials.

· Chemical and Industrial Screening: Resistant to chemicals and suitable for industrial processing lines.

· Food Processing and Agriculture: Non-clogging and safe for handling agricultural materials.

Advantages:

● Extended service life due to high wear resistance

● Reduced maintenance and replacement costs

● Improved screening efficiency with a non-clogging design

● Quieter operation compared to metal screens

● Resistant to corrosion, chemicals, and moisture

● Lightweight and easy to install

Polyurethane Wire Screens are a modern and reliable screening solution, offering a perfect balance of durability, flexibility, and efficiency. Their unique combination of polyurethane and steel wire construction makes them an ideal choice for demanding screening applications across various industries.

For more information, please visit our website.

Polyurethane Wire Screen, also called polyurethane screen mesh or PU screen mesh, is a high-performance screening solution designed for industries that require efficient and durable material separation. Made from premium polyurethane material, this type of screen combines the flexibility and wear resistance of polyurethane with the structural strength of embedded steel wires. It is one of the most reliable options among polyurethane screens widely used today.

Introduction:

The polyurethane wire screen mesh is engineered to withstand the toughest screening environments. It offers superior wear resistance compared to traditional metal screens while maintaining structural integrity thanks to its embedded steel wire framework. This unique design ensures long-lasting performance, reduced downtime, and improved screening accuracy.

Applications span across mining, quarrying, aggregate production, recycling, and other heavy-duty industries, making PU screen mesh an ideal choice for material separation where durability and efficiency are critical.

Key Features

Material Options: Stainless steel (304, 316, etc.), carbon steel, or other alloy wires.

Slot Geometry: Parallel long slots with uniform width (e.g., 0.1mm–10mm) and customizable lengths.

Weaving Technique: Crimped pre-woven wires locked vertically and horizontally for rigidity.

Advantages: High throughput, anti-clogging design, wear resistance, and structural stability.

For additional screening options, you may also explore our polyurethane screen panels and other polyurethane screens.

Applications:

Our polyurethane screen mesh is widely applied in:

· Mining and Mineral Processing: Efficient separation of ores, coal, and aggregates.

· Aggregate and Sand Processing: Reliable performance in quarries and sand plants.

· Recycling and Waste Management: Effective for sorting scrap, plastics, and construction waste.

· Construction and Demolition: Screening concrete, rubble, and other demolition materials.

· Chemical and Industrial Screening: Resistant to chemicals and suitable for industrial processing lines.

· Food Processing and Agriculture: Non-clogging and safe for handling agricultural materials.

Advantages:

● Extended service life due to high wear resistance

● Reduced maintenance and replacement costs

● Improved screening efficiency with a non-clogging design

● Quieter operation compared to metal screens

● Resistant to corrosion, chemicals, and moisture

● Lightweight and easy to install

Polyurethane Wire Screens are a modern and reliable screening solution, offering a perfect balance of durability, flexibility, and efficiency. Their unique combination of polyurethane and steel wire construction makes them an ideal choice for demanding screening applications across various industries.

For more information, please visit our website.

SEND INQUIRY

Please fill in fully your information to send email

CATEGORY

Agriculture

Agriculture