Contact person: Mr. Arlan

Position:

Address: South Taoqiu Industrial Park, Pangcun Town,Dingzhou City

Country: China

Phone: - Mobi: 13613122913

11FFG Series Mattress Recycling Equipment

Price:

4.

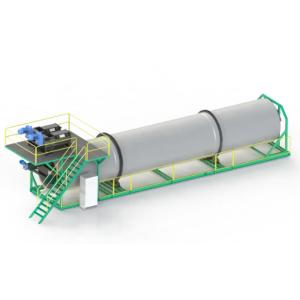

11FFG Series Mattress Recycling Equipment

Equipment parameters

Equipment size: 15*3.1*3.1m (11FFG-66 type) can be customized according to needs

Total volume: 66m³ (11FFG-66 type) can be customized according to needs

Dry matter content of bedding: 45%-55%

Bedding output: 12-15 tons/day (11FFG-66 type) can be customized according to needs

Tank material: 10mm thick fiberglass tank + 30mm foamed polyurethane insulation layer (11FFG-66 type) can be customized according to needs

Drive unit: Single 7.5kw/11kw hard gear reducer

Weight: 17 tons (determined by equipment model)

Total power: 12kw

Power supply: 3-phase 4-wire AC380V

Equipment introduction

The main principle of the bedding regeneration system is that the manure water cleaned from the cowshed is concentrated in the pool for stirring, and then transported by the cutting pump to the solid-liquid separator for solid-liquid separation. The separated dry matter continuously enters the fermentation drum. At the same time, under the automatic control of the program, the fan sends the required oxygen in the drum into the fermentation drum, so that the material can be fully aerobic fermented.

This process does not require additional access to bacteria, and does not rely solely on external energy for heating. In the early stage of fermentation, the material is basically medium temperature (30℃-40℃), and mesophilic bacteria are more active and multiply in large quantities. As the temperature continues to rise, mesophilic bacteria are inhibited or even die, while the reproduction of thermophilic bacteria enters an exciting state. The large-scale reproduction of thermophilic bacteria and the obvious increase in temperature cause the fermentation to directly enter high temperature (50℃-75℃) and stabilize within the high temperature range for a period of time. Within this temperature range, the time lasts for 8-24 hours, and the parasites, pathogens and eggs in the fermented cow dung are killed, with a killing rate of 99.9%. The control program will automatically start the fan to prevent the fermentation temperature from rising too high, and change the speed of the fermentation tank to control the discharge speed and moisture content of the material.

The fermentation time of the material is about 24 hours, and the temperature in the tank is maintained at 55℃-75℃, eventually the material reaches a moisture content of 45-53%, so that it can be backfilled into the cowshed as bedding material.

Equipment advantages

High height and high sterilization rate

The two key control points of cow dung recycled bedding are moisture content and sterilization rate. The cow bedding recycled bedding production equipment developed by Sifeng Environmental Protection can control the moisture content of the bedding produced between 45% and 53%, meeting the standard of bedding; the worm egg removal rate can reach 100%, and the removal rate of Escherichia coli, Streptococcus, Staphylococcus aureus and Klebsiella and other dairy cow mastitis pathogens can reach 99.9%. Compared with traditional methods such as stacking fermentation, strip fermentation, and film fermentation, it has the advantages of high material dryness, high sterilization rate, small footprint, and short fermentation time.

The bedding is soft and the cows are comfortable

The particle size distribution of the cow dung recycled bedding produced by the equipment is <1.0mm accounting for 34.81%, 1.0~2.0mm accounting for 38.42%, and >2.0mm accounting for 26.77%, which can provide a more comfortable lying environment for cows. The fibers in the cow dung are fully softened in the cow bed recycled bedding production equipment, which will not cause any discomfort to the cow's udder, thereby ensuring the health of the cow's udder. It is a high-quality bedding for backfilling the cowshed.

Long service life and low failure rate

The fermentation drum is the core component of the equipment. It is made of 30mm thick composite material in one piece. From the inside to the outside, it is a wear-resistant and anti-corrosion layer, a temperature-resistant insulation layer, a glass fiber reinforcement layer, and a high-density insulation layer; at the same time, the outside of the equipment tank is attached with a 50mm thick high-density foamed polyurethane to better isolate the external temperature interference. It can also be used in cold areas. The parts of the equipment that come into contact with manure are all composite materials or stainless steel. The control unit ensures that the equipment can work for a long time in a manure environment that is prone to corrosion and oxidation.

The equipment has low energy consumption and high processing efficiency.

The rated power of the fermentation drum unit is only 7.5Kw. Together with the aeration system and the transmission system, the total power of the fermentation drum unit is about 20KW. The drive motor can be adjusted dynamically in real time according to the amount of material in the cabin, and start differently. At the same time, it can achieve smooth start and stop with the cooperation of the overrunning clutch, with the advantages of low power consumption, ultra-quiet and ultra-long service life;

The equipment can achieve rapid fermentation treatment for 24 hours, and the feeding and discharging can be carried out at the same time, which does not affect the overall manure treatment process and ensures the daily bedding needs of the ranch.

High degree of automation, saving labor costs

The whole system has multiple built-in sensor units and intelligent electronic control systems. It can realize real-time dynamic monitoring, data collection and statistics, and remote early warning through the phone card cloud APP; combined with the on-site camera, it can monitor the feeding and discharging in real time. The control system adopts Siemens PLC control unit, which can realize remote detection, remote control, automatic start and stop and other functions.

Please visit our website for more information.

SEND INQUIRY

Please fill in fully your information to send email

CATEGORY

Agriculture

Agriculture