Contact person: Mr. Guan

Position: SHENYANG

Address: china liaoning shenyang tianci5-1E-mail:chinamech@outlook.com

Country: China

Phone: 13998171597 - Mobi:

calcinator

Price:

Swirl dynamic calciner is my company again in 1997 successfully developed China's first dynamic calcined powder materials for equipment, and obtained national patent

Products

Calcining the modification, purification, decomposition, oxidation, reduction, chemical process, during calcining the material was static and dynamic motion, the larger the specific surface area when calcined material, the faster the heat transfer rate, the shorter the calcination time. Dynamic swirl calcination powder material is heated with hot air to form mixed counter flow heat exchange surface area to achieve the maximum instantaneous calcination, is to ensure adequate heat decomposition, improve product quality of the new process equipment.

- Works

- Calciner mainly by gas heaters, gas-solid mixers, calciner furnace, gas-solid separator collector components. Pre-calcined material from the gas-solid mixer into the furnace, a gas heater with hot air heated mixture was swirling motion state, calcination is completed in an instant from the calciner exit into the gas-solid separator, after the separation of solids and gas, respectively, from the discharge port and the exhaust discharge port.

- Features

- Continuous operation, temperature-controlled, gas-solid mixing fully, the product quality and stability.

- Instant calcined product without over-burning, is conducive to active production.

- Closed system, environmental pollution, high recovery, civilized production.

- Can be equipped with combustion exhaust gas cooler, drier system combinations, effective use of thermal energy.

- Exhaust gas recycling system configuration, can be gas treatment and utilization

- Temperature of hot air calcining furnace 500-1600 ℃

- Calcined material particle size <60 mesh.

- Burning fuel, solid (coal), gas (gas, natural gas), liquid (oil, heavy oil).

- Combustion: indirect, direct, external ignition.

Powdery granular material decomposition

- Basic Configuration

- Devices are normally produced by the wind system is slightly negative pressure, obtained by direct or indirect sources of heat, burning exhaust using cyclone, air-cooled, bag, electrostatic or washing the air purification and product recovery.

- Calcining combination with drying system configuration

- For effective use of exhaust gas energy conservation, the calcination exhaust some additional drying apparatus, the pre-calcined material can preheat temperature and dehydration to reduce exhaust emissions, efficient use of energy.

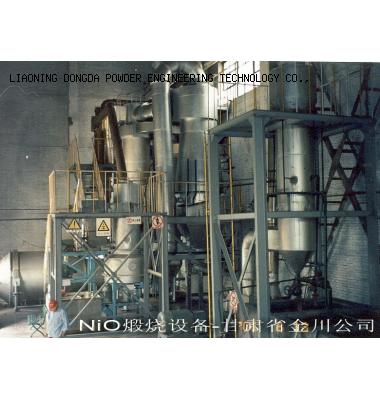

- Calciner industrial applications

- Widely used in chemical, building materials, mining and other industries, the following is a typical property cases

- Chemical industry

- Magnesium, zinc, iron, lithium, nickel, aluminum, cobalt hydroxides, rare earth oxides, barite, cryolite, vanadium pentoxide, manganese sulfate, soda ash

- Building Materials Mining

- Ascharite hemihydrate gypsum, kaolin, brucite, calcium carbonate, molybdenum trioxide, fluorine powder, magnesite, etc.

- • Our company can provide different specifications furnace, design and on-site installation of special calcining process furnaces can be dedicated matching design.

- • Provide industrial furnace test equipment, to meet the test requirements for different materials.

技术规格

参数\单位\型号

SKDS30

SKDS50

SKDS80

SKDS100

SKDS140

SKDS180

SKDS250

SKDS350

SKDS450

热气体

流量

m3/h

1200-

1500

3500-

4200

9000-

11000

14000-

17000

14000-

33000

50000-

70000

85000-

140000

95000-

270000

280000-

450000

煅烧炉

外形

尺寸

直径

m

1.3

1.6

2.4

2.6

3.0

3.4

4.0

5.0

6.2

高度

m

5-7

5-7

5-7

8-10

10-15

10-15

15-20

15-20

20-25

热源强度

Kcal/h

15-

20(104)

40-

50(104)

100-

130(104)

170-

200(104)

300-

400(104)

300-

400(104)

1000-

1600(104)

1200-

3000(104)

3200-

5000(104)

系统占

地面积

m2

(LXW)

8×8

10×10

12×12

15×15

16×16

20×20

25×25

25×25

30×30

SEND INQUIRY

Please fill in fully your information to send email

CATEGORY

Agriculture

Agriculture