Supplier: Yuanlv Filter Equipment Co., Ltd.

Contact person: Ms. Xindi Ke

Position:

Address: Jinling Mansion 2-3-403,Yuhua Road,Shijiazhuang,Hebei,China

Country: China

Phone: 86-18032153916 - Mobi: 86-18032153916

Wedge Wire Single Filter Nozzle

Price: custom

Our wedge wire filter nozzle is manufactured from stainless steel material or custom material. The wedge wire nozzle features non-clogging, high filtering efficiency and economical. It has a wide range of applications in water treatment applications. The different wedge wire sizes and slot sizes can suit different class filtration. So we provide the custom service.

Advantages of Wedge Wire Screen Filter Nozzle:

1. Type 316L stainless steel construction.

2. Continuous slot design provides an increased open area for better collection.

3. Standard nozzles are 2in./51mm diameter and can be attached to the plate either with threaded end fittings or with“L” bolts.

4. Standard slot opening is typically range between 0.006”(0.15mm), and 0.020in./0.50mm wide suitable for 40 to 50 mesh size media, Other slot sizes are also available.

5. The wedge wire screen is highly resistant to plugging.

6. Choice of either 3/4” NPT or 1” NPT fittings are available from stock. Other styles, such as tee-bolt mountings, and drop tubes are readily available.

7. Less expensive than other screens of equal efficiency.

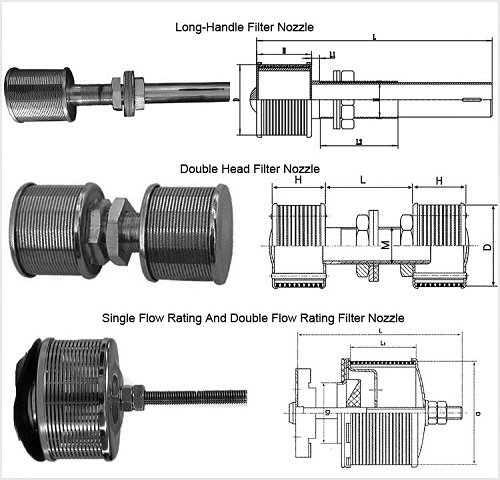

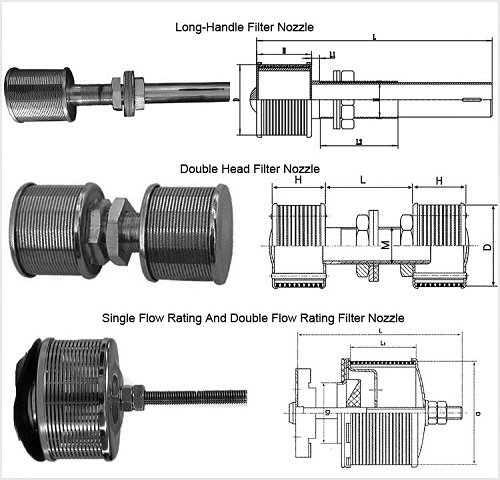

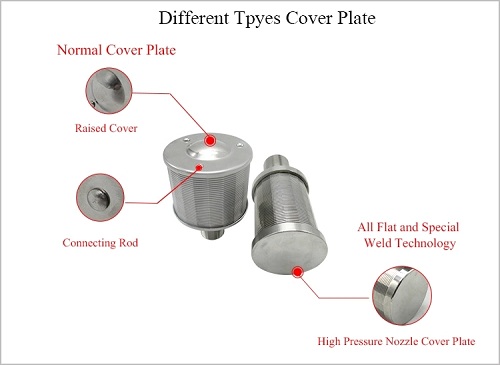

Different Type of Wege Wire filter nozzle:

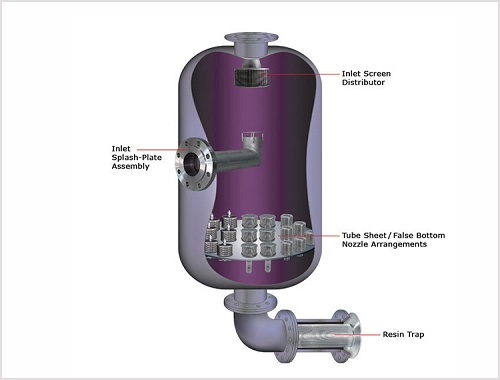

Usage of Wedge Wire Screen Filter Nozzle

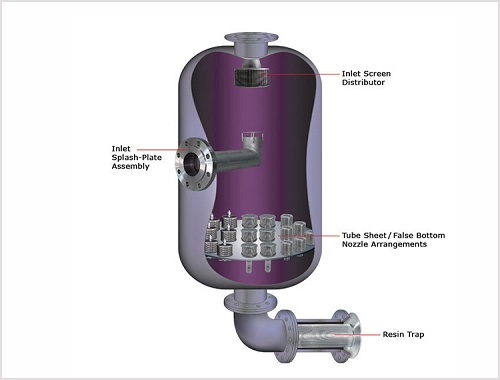

Wedge wire filter nozzles are used widely in down-flow reactors for liquid/solid or gas/solid separation. The liquid or gas can flow through the nozzles while the solids are retained in the vessel by the nozzles.

By optimizing the ratio between the head loss of each component (open area and fitting) we can determine the optimum quantity of nozzles to ensure a perfect distribution or collection without channeling, wall effects, or dead zones.

E-mail: admin@yuanlvfilter.com

Advantages of Wedge Wire Screen Filter Nozzle:

1. Type 316L stainless steel construction.

2. Continuous slot design provides an increased open area for better collection.

3. Standard nozzles are 2in./51mm diameter and can be attached to the plate either with threaded end fittings or with“L” bolts.

4. Standard slot opening is typically range between 0.006”(0.15mm), and 0.020in./0.50mm wide suitable for 40 to 50 mesh size media, Other slot sizes are also available.

5. The wedge wire screen is highly resistant to plugging.

6. Choice of either 3/4” NPT or 1” NPT fittings are available from stock. Other styles, such as tee-bolt mountings, and drop tubes are readily available.

7. Less expensive than other screens of equal efficiency.

Different Type of Wege Wire filter nozzle:

Usage of Wedge Wire Screen Filter Nozzle

Wedge wire filter nozzles are used widely in down-flow reactors for liquid/solid or gas/solid separation. The liquid or gas can flow through the nozzles while the solids are retained in the vessel by the nozzles.

By optimizing the ratio between the head loss of each component (open area and fitting) we can determine the optimum quantity of nozzles to ensure a perfect distribution or collection without channeling, wall effects, or dead zones.

E-mail: admin@yuanlvfilter.com

SEND INQUIRY

Please fill in fully your information to send email

CATEGORY

Agriculture

Agriculture