Supplier: Shanghai Qipang Industrial Co., Ltd

Contact person: Mr. zhao

Position:

Address: Anting,Jiading District, Shanghai

Country: China

Phone: - Mobi: +86 15001830288

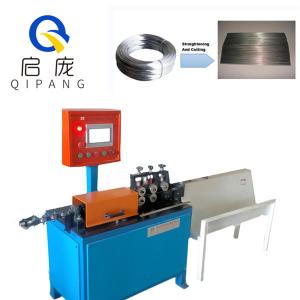

High-Quality Cable Straightening Cutting Machine

Price:

High-Quality Cable Straightening Cutting Machine

1.We have CE&SGS certification ,ISO1990 Quality system certification ,so on...

2. Good quality and professional pre - sales, after - sales service.

3.13 years of development, manufacturing and marketing experience, the main customers are: North America (United States, Canada, Mexico), Europe (Italy, Britain, France, Poland, Netherlands), Southeast Asia, etc.

4. Flexible development and customization CEM COM.

5. Excellent consulting team covering the world.

6. Fast spare parts distribution and sufficient inventory.

This Cable Straightening Cutting Machine can be suitable for all kinds of metal wire straightening cutting, surface, no scratches, cutting length error of 0.2-0.5 mm, and the cutting length range is 80mm to 6000mm. Human-machine incorporate touch screen control system can save manpower for the customer. The company's main range of wire 1 mm to 5 mm can be customized, fastest of up to 150 meters per minute, available for copper, iron, aluminum, gold, silver, stainless steel, high carbon steel and plastic coated wire, metal wire. If you want faster speed for cable straightening cutting machine, please contact customer service. If you are concerned about the straightening effect, we can provide free proofing.

Configuration parameters of Cable Straightening Cutting Machine:

1 two servo motors, 1.5 kw traction and 1:10 planetary reducer, cut off 1.5 kw,

2 cut off the PLC touch screen electronic CAM system,

3 servo motor brand, servo motor

4 fuselage length 1850mm wide 780mm total height 1300mm.It weighs about 498 kilograms.

5 the total weight of the automatic spreader is 90kg.

6 The control mode includes inverter analog control system,

7 Minimum diameter: 250mm; maximum diameter: 500mm;

8 the weight of the spreader is about 90kg"

QIPANG has long-term cooperation with important customers and believes that important customers are reliable partners for those who need high-quality straighteners, wire guides, cutting devices and laminating machines.

Since 2008, Cometo's working methods have been provided by the wishes of the founders David wang Tocchetti, from 360 ° control of the supply chain from equipment design to parts production. Continued investment in product development keeps QIPANG at the forefront and provides competitive products in terms of quality and price.

Since 2011, in addition to the equipment used to process wires, cables and pipes, which has been a feature of the Cometo product range, Cometo has put its capabilities and expertise into practice in the manufacture of thread cutting machines equipped with unwinders. A major achievement and international honor in the company's history, the production of machines serving the thread industry is destined to be more and more, providing customers around the world with customized solutions designed according to specific needs to provide products designed for each production Designed for reality.

1.We have CE&SGS certification ,ISO1990 Quality system certification ,so on...

2. Good quality and professional pre - sales, after - sales service.

3.13 years of development, manufacturing and marketing experience, the main customers are: North America (United States, Canada, Mexico), Europe (Italy, Britain, France, Poland, Netherlands), Southeast Asia, etc.

4. Flexible development and customization CEM COM.

5. Excellent consulting team covering the world.

6. Fast spare parts distribution and sufficient inventory.

This Cable Straightening Cutting Machine can be suitable for all kinds of metal wire straightening cutting, surface, no scratches, cutting length error of 0.2-0.5 mm, and the cutting length range is 80mm to 6000mm. Human-machine incorporate touch screen control system can save manpower for the customer. The company's main range of wire 1 mm to 5 mm can be customized, fastest of up to 150 meters per minute, available for copper, iron, aluminum, gold, silver, stainless steel, high carbon steel and plastic coated wire, metal wire. If you want faster speed for cable straightening cutting machine, please contact customer service. If you are concerned about the straightening effect, we can provide free proofing.

Configuration parameters of Cable Straightening Cutting Machine:

1 two servo motors, 1.5 kw traction and 1:10 planetary reducer, cut off 1.5 kw,

2 cut off the PLC touch screen electronic CAM system,

3 servo motor brand, servo motor

4 fuselage length 1850mm wide 780mm total height 1300mm.It weighs about 498 kilograms.

5 the total weight of the automatic spreader is 90kg.

6 The control mode includes inverter analog control system,

7 Minimum diameter: 250mm; maximum diameter: 500mm;

8 the weight of the spreader is about 90kg"

QIPANG has long-term cooperation with important customers and believes that important customers are reliable partners for those who need high-quality straighteners, wire guides, cutting devices and laminating machines.

Since 2008, Cometo's working methods have been provided by the wishes of the founders David wang Tocchetti, from 360 ° control of the supply chain from equipment design to parts production. Continued investment in product development keeps QIPANG at the forefront and provides competitive products in terms of quality and price.

Since 2011, in addition to the equipment used to process wires, cables and pipes, which has been a feature of the Cometo product range, Cometo has put its capabilities and expertise into practice in the manufacture of thread cutting machines equipped with unwinders. A major achievement and international honor in the company's history, the production of machines serving the thread industry is destined to be more and more, providing customers around the world with customized solutions designed according to specific needs to provide products designed for each production Designed for reality.

SEND INQUIRY

Please fill in fully your information to send email

CATEGORY

Agriculture

Agriculture