Supplier: JRH Engineering

Contact person: Mr. Bhavik Patel

Position: owner

Address: Vishwakarma Industrial Estate

Country: India

Phone: - Mobi: 7046278859

MS Flange Manufacturer

Price: 9500

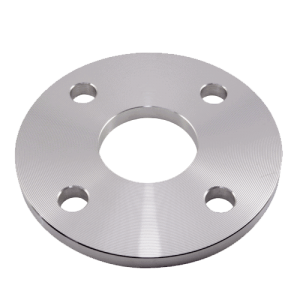

The MS Flange by JRH Engineering Company is a high-quality mild steel flange designed for robust industrial applications. Manufactured to precise specifications, it offers excellent durability and reliability in various piping systems. Ideal for connecting pipes, valves, and other equipment, the MS Flange ensures a secure and leak-proof joint, making it a trusted choice for engineers and technicians.

In the realm of industrial engineering, the significance of reliable and durable components cannot be overstated. One such crucial component is the MS flange, a product that plays a pivotal role in the assembly and maintenance of piping systems. MS flanges, made from mild steel, are integral to ensuring the safe and efficient operation of various industrial processes. This article delves into the features, applications, and benefits of MS flanges, with a spotlight on the offerings from JRH Engineering Company.

What is an MS Flange?

MS flanges are mechanical connectors made from mild steel, a material known for its malleability and ductility. These flanges are designed to join pipes, valves, pumps, and other equipment to form a complete piping system. The primary purpose of an MS flange is to provide a secure and leak-proof joint, which is essential for the safe transportation of fluids and gases.

Key Features of MS Flanges

MS flanges are used across a multitude of industries, including:

JRH Engineering Company stands out as a leading manufacturer of high-quality MS flanges. With a commitment to precision engineering and stringent quality control, JRH Engineering delivers products that meet and exceed industry standards. Their MS flanges are crafted with meticulous attention to detail, ensuring optimal performance and longevity.

Why Choose JRH Engineering's MS Flanges?

In the realm of industrial engineering, the significance of reliable and durable components cannot be overstated. One such crucial component is the MS flange, a product that plays a pivotal role in the assembly and maintenance of piping systems. MS flanges, made from mild steel, are integral to ensuring the safe and efficient operation of various industrial processes. This article delves into the features, applications, and benefits of MS flanges, with a spotlight on the offerings from JRH Engineering Company.

What is an MS Flange?

MS flanges are mechanical connectors made from mild steel, a material known for its malleability and ductility. These flanges are designed to join pipes, valves, pumps, and other equipment to form a complete piping system. The primary purpose of an MS flange is to provide a secure and leak-proof joint, which is essential for the safe transportation of fluids and gases.

Key Features of MS Flanges

- Durability: Mild steel offers excellent strength and durability, making MS flanges suitable for high-pressure applications.

- Corrosion Resistance: While mild steel is not inherently corrosion-resistant, MS flanges are often treated or coated to withstand corrosive environments.

- Versatility: Available in various sizes and configurations, MS flanges can be customized to meet specific project requirements.

- Ease of Installation: The design of MS flanges allows for straightforward installation and maintenance, reducing downtime and labor costs.

MS flanges are used across a multitude of industries, including:

- Oil and Gas: In pipelines transporting crude oil, natural gas, and other hydrocarbons.

- Chemical Processing: Where reliable connections are crucial for handling corrosive substances.

- Water Treatment: In the assembly of systems for water purification and distribution.

- Power Generation: In boiler systems and other high-pressure environments.

- Construction: For plumbing and HVAC systems in commercial and residential buildings.

- Cost-Effective: Mild steel is relatively inexpensive compared to other materials, making MS flanges a cost-effective choice for many applications.

- Strength and Stability: MS flanges provide robust connections that can handle significant stress and pressure.

- Flexibility: The ability to customize flanges to specific needs ensures optimal performance in diverse applications.

- Maintenance: Easy to disassemble for inspection, cleaning, or repairs, MS flanges contribute to efficient maintenance routines.

JRH Engineering Company stands out as a leading manufacturer of high-quality MS flanges. With a commitment to precision engineering and stringent quality control, JRH Engineering delivers products that meet and exceed industry standards. Their MS flanges are crafted with meticulous attention to detail, ensuring optimal performance and longevity.

Why Choose JRH Engineering's MS Flanges?

- Quality Assurance: Each flange undergoes rigorous testing to ensure it meets the highest quality benchmarks.

- Custom Solutions: JRH Engineering offers bespoke flange solutions tailored to specific project requirements.

- Expertise: With years of experience in the field, JRH Engineering provides unmatched technical support and guidance.

- Innovation: The company continually invests in advanced manufacturing technologies to produce cutting-edge products.

SEND INQUIRY

Please fill in fully your information to send email

CATEGORY

Agriculture

Agriculture